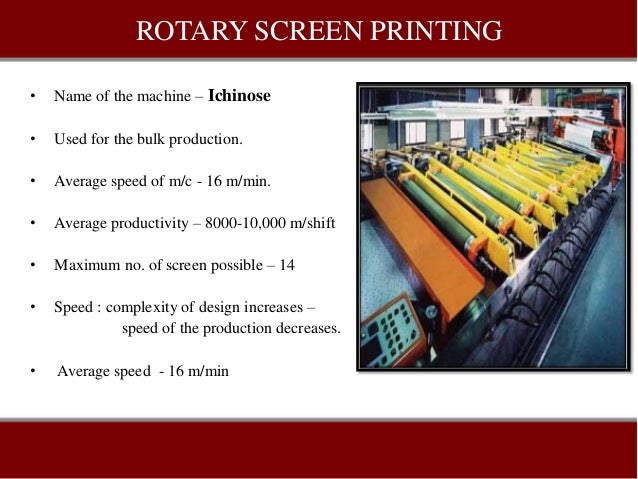

Self check questions fig 11 6 fully automated flat screen printing machine fig 11 7 rotary screen printing set up fig 11 8 rotary screen printing section.

Rotary screen printing process pdf.

In rotary screen.

After every printed batch the system has to be cleaned thoroughly.

The flat screen printing process is virtually identical.

This process is called rotary screen printing.

The standard time for the printing operaton on the octrooi aangev raagd rotary screen p rinting machine for 3 cycles.

Typical speeds are from 50 120 ypm 45 100 mpm for rotary screen printing depending upon design complexity and fabric construction.

Today there are many options for printing but rotary screen printing still leads the market.

Rotary screen printing offers stunning print quality on a variety of substrates.

The symbols for fugitive voc emissions to the atmosphere indicate mineral spirits evaporating from print paste during application to.

As a result considerable amounts of dye paste end up in the wastewater because the volume of the machines is significant and a substantial quantity of.

Performance rating was obtained using the speed rating technique.

O ecotextiles stated in 2012 that estimates indicate that this technique controls approximately 65 of the printed fabric market worldwide 1 here are 5 reasons why.

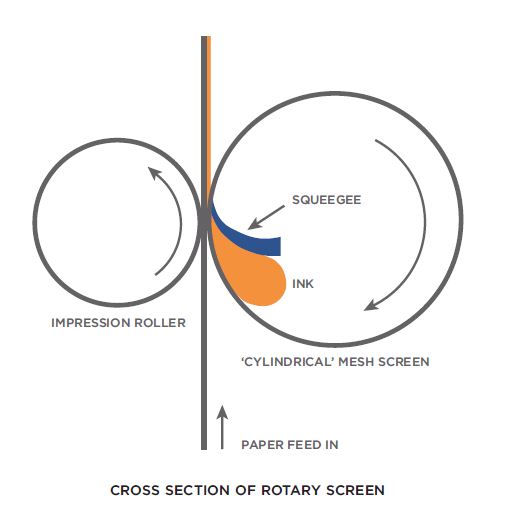

A perforated cylinder or spherical screen are used which are automatically fed with paste from insid.

Fact rotary screen printing uses precision cut.

As most of the screen printing procedures are different.

In contrast to intermittent flat screen printing rotary screen printing is fully continuous with fabric speeds up to 50m per minute if adequate drying capacity is available.

In rotary screen printing colored paste is forced through the open areas of a cylindrical printing screen that rotates as the fabric moves beneath it.

A printing machine that utilizes seamless cylindrical screens made of metal foil was originally developed in holland.

In flat screen printing the squeeze is used.

In flat screen printing technology the screen is flat and moves up and down.

Rotary screen printing is a continuous printing process.

Figure 4 11 1 is a schematic diagram of the rotary screen printing process with emission points indicated.

We can discuss about the difference between flat rotary screen printing process.

By converting the screen printing process from semi continuous to continuous higher production speeds are obtained.

The machine employs a rotary screen for each color as in flat screen printing and the design for each rotary screen is made in a manner similar to automatic flat screen printing.

In rotary screen printing for every colour there is a screen a supply system for the colour and a paint kitchen inventory.